The launch of the TUBALL™ nanotubes is aiming to change the landscape of the packaging industry in a drastic way as this new technology promises to considerably improve the properties of countless materials used in manufacturing and other stages of the supply chain. (Related Topic:┬áprotective packaging,┬áVCI paper,┬ámoisture barrier bags)

Many companies have already embarked on a race to take the lead in developing several dispersion technologies to enable customers in the incorporation of new products that wonÔÇÖt alter negatively their manufacturing technology or formulation.

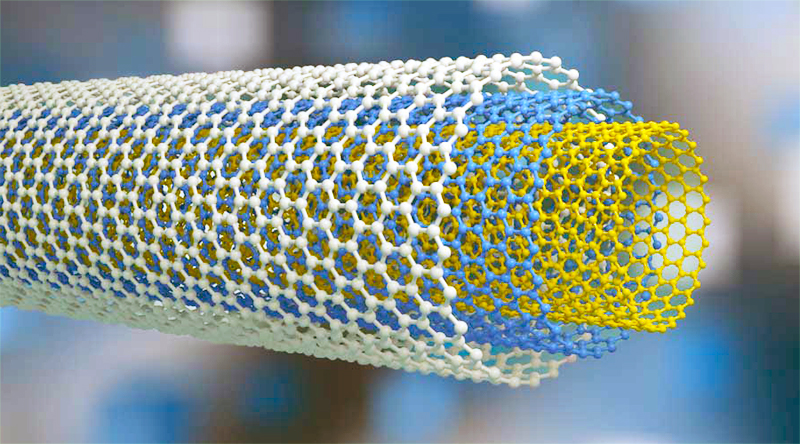

Graphene nanotubes offer a broad range of qualities that are 100 times stronger than steel, provide excellent conductivity, feature anti-static properties, and thermal stability up to 1000┬░C, amongst several other key advantages such as the possibility to achieve the desired properties with rather low loadings of the additive.

RELATED: Edco Supply Corporation is a leading packaging expert that specializes in protective packaging such as moisture barrier bags and VCI paper. They offer military spec packaging solutions to anyone in need. You can get in touch with them by calling at 1-800-221-0918.

OCSiAl, a startup founded in Novosibirsk, a remote location in Siberia and a stronghold of Russian science that has grown into a Luxembourg based global business, stands by the purpose of its creation: generating a technology that allows to practically and economically producing graphene nanotubes under the brand name TUBALL™.

In order to facilitate the effective incorporation of TUBALL™ into materials, the OCSiAl team has developed a line of easy-to-use pre-dispersed concentrates, masterbatches and other suspensions that are compatible with a wide variety of industry-standard formulations.

This new additive can be used to nano augment and improve the characteristics of nearly 70% of all materials in existence, although the initial focus is still on plastics, energy, rubbers, and composites. Nevertheless, OCSiAl has already developed solutions for thermoplastics, LDPE and PE for the blown film industry and protective packaging thanks to its anti-static properties.